Posted: August 31, 2025

Photo: Solimpeks

Türkiye is a leading solar heat nation in various areas. It was the third largest market in terms of new solar collector capacity in 2024 after China and Brazil. Systems with a record 19.4 GW were in operation at the end of 2023. With its high solar radiation level, even solar concentrating heat solutions achieve reasonably short payback periods. For these reasons, Türkiye plays a crucial role as a member of the IEA Solar Heating and Cooling Programme. But conversely, Turkish scientists also benefit from exchanges with experts from around the world.

One such scientist is Associate Professor Dr. Feride Sener Yilmaz from the lighting research group at the Istanbul Technical University (ITU): "We value the opportunity to engage directly with globally recognized experts in the field of lighting. Such collaboration brings significant academic and practical benefits." She also emphasized the importance of workshops and design guidelines that support low-carbon development in Türkiye - a developing country in the lighting sector.

At ITU, researchers are studying the impact of double-skin facades on enhancing view quality and daylight performance. They actively contribute to IEA SHC Task 70 on Low-Carbon, High-Comfort Integrated Lighting. In a current survey, they evaluated daylight performance of existing university buildings with double-skin façades. This evaluation was based on the current European standard (EN17037) and a user questionnaire. The goal was to understand how double-skin façades affect occupants’ visual experience and to propose optimized solar control devices for such façades.

“It is very encouraging for Turkish researchers to collaborate directly with international expert groups within the IEA SHC framework,” said Kemal Gani Bayraktar, who represents Türkiye on the IEA SHC Executive Committee. He played a key role in transitioning the national representation from Turkish Society of HVAC and Sanitary Engineers (TTMD) to a new institution. As a result, the Turkish Energy, Nuclear and Mineral Research Agency (TENMAK) is now the official contracting party to the IEA SHC Programme, but TTMD will still coordinating the work, according to Bayraktar.

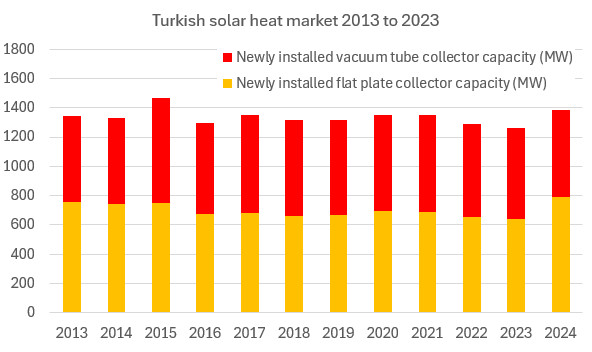

Turkish solar thermal market between 2013 and 2024

Source: Solar Heat Worldwide / Bural

Post-earthquake housing boom fuels solar collector demand in Türkiye

"2024 was a very good year in terms of new collector sales", reported Kutay Ulke, Sales Director at Bural Solar, one of the leading collector and tank manufacturers in Türkiye. Ulke has contributed national market data to the Solar Heat Worldwide Report for many years.

The surge in demand was largely driven by new housing construction following the devastating 2023 earthquake. In 2024 alone, the Housing Development Administration (TOKI) built 155,124 apartments across eleven cities. A significant proportion of these units were equipped with centralized pumped solar water heating systems for domestic hot water. These systems typically consist of 14 to 30 flat-plate solar collectors and 1,000 to 2,000-litre hot water storage tanks.

Ulke estimates the newly installed collector area in this field to be around 217,000 m2, which increased the market volume by 10 % last year. TOKI did not allow vacuum tube collectors within the public tendering, because they do not have Solar Keymark certificates and are not adapted for forced circulation systems.

In total, nearly 1,400 MW (equivalent to 2 million m²) of solar thermal collectors were installed across Türkiye in 2024 - the vast majority of which were produced domestically. Like other major collector markets, Türkiye has a strong local flat-plate collector manufacturing base.

While vacuum tube collectors are still widely used for residential hot water systems, their market share in Türkiye is slowly declining. This is largely due to the ongoing expansion of the natural gas grid, which provides an affordable alternative for household heating.

Interestingly, Türkiye's vacuum tube collector sector has evolved differently from global trends. Following the introduction of a protective tax in 2011, several local manufacturers emerged, now producing coated glass tubes and assembling complete systems domestically. In contrast, most vacuum tube collectors used globally are manufactured in China and exported worldwide.

New additional factory of Bural Solar in Kayseri – opened in 2023

Photo: Bural Solar

Expanded solar thermal production capacities

Like their counterparts in Greece, some Turkish flat-plate collector manufacturers are strong in exports. These companies have invested heavily in recent years. Notable examples include Bural, based in Kayseri, which completed construction of a new 5,000 m² factory in July 2023. The new facility enables a more streamlined production process and significantly improves logistics, with enhanced loading and unloading capacities.

Solimpeks, headquartered in Konya, around 300 km south of Ankara, has substantially expanded its product portfolio. The company recently established a dedicated factory for enamelled storage tanks just a few kilometres from its main facility. This new site also houses an assembly line for heat pumps (see photo above).

In addition to its production expansion, Solimpeks has implemented a largely green energy system to power its existing collector and storage tank factory. The setup includes a 59?kW photovoltaic-thermal (PVT) installation, a 321?kW PV system, a 150?kW heat pump, a 1,000-litre hot water heat pump, and 12,000 litres of hot water storage capacity.

New Solimpeks factory for enamelled tanks with a capacity of 150,000 units per year and a heat pump assembly line for 30,000 units annually. The electricity demand of the new factory is covered by a 1.4 MW PV generator on the roof.

Photo: Solimpeks

Concentrating solar heat as a competitive alternative to fossil fuel boilers

While most solar thermal systems in Türkiye are used for residential water heating, installations have also been implemented in hotels, hospitals, prisons, and other large facilities. According to the Solar Heat Worldwide report, this has placed Türkiye second only to China in terms of the number of large-scale systems in operation.

However, concentrating solar thermal (CST) technologies for industrial applications remain a niche segment. Professor Ibrahim Halil Yilmaz from Adana Alparslan Türkes Science and Technology University (ATU) sees several structural barriers limiting the growth of CST in Türkiye: "There are no commercial-scale manufacturers of concentrating solar collectors operating. While a few demo system producers exist, their activity in the sector is limited and often inconsistent", he said. "In addition, the country faces a shortage of qualified personnel with the expertise to implement and adapt CST technologies effectively."

One notable past player in Türkiye's concentrating solar thermal sector was Soliterm Günes Enerjisi Teknolojileri, a subsidiary of the German company Soliterm. Based in Ankara, the company was active until 2023, but has since ceased operations in Türkiye and shifted production to Germany, according to company information.

In an effort to raise awareness of concentrating solar thermal (CST) solutions in Türkiye, the Turkish-German Energy Partnership commissioned the German engineering firm Fichtner to conduct a pre-feasibility study for a major industrial site: the Ak Gida dairy plant in Kahramanmaras, southern Türkiye.

Fichtner began by identifying available space at the facility. Based on the full utilization of 10,000 m² of land area and an additional 10,000 m² of rooftop space, their analysis showed that a parabolic trough collector field could meet 42% of the factory's heat demand at temperatures exceeding 150°C. The 4.8 MW system was found to have a payback period of around seven years, even without subsidies.

Fichtner concluded that concentrating solar heat offers a competitive alternative to conventional systems, with significant potential for reducing energy costs and fossil fuel consumption.

Professor Ibrahim Halil Yilmaz sees the promotion of hybrid energy systems as one of the most promising pathways forward. These could include combinations of PV and CST, CST with heat pumps, or other multi-source configurations, all aimed at enhancing system efficiency and economic viability.

|

Client

|

Dairy Ak Gida, Türkiye

|

|

Site

|

Kahramanmaras, southern Turkey

|

|

Annual specific irradiation on site

|

2,150 kWh/m2

|

|

Heat demand of factory

|

19.3 GWh annually

|

|

Required heat temperature in factory

|

Steam network with temperatures above 150 °C

|

|

Current heat supply system

|

Gas boilers

|

|

Type of collector field

|

Parabolic trough collectors for direct system production without storage

|

|

Size of collector field

|

4.8 MWth / 8,300 m2 aperture area

|

|

Solar fraction of heat demand of the factory

|

42 %

|

|

Limitations of the variant

|

Available area on ground (10,000 m2) and on a factory building (10,000 m2) were fully utilized

|

|

Payback period without subsidies

|

6.9 to 7.4 years

|

|

Payback period with potential subsidies

|

5.1 to 5.4 years

|

Key data of the case study calculation by Fichtner, Germany

Source: Turkish-German Energy Partnership (dena)

3 MW solar space heating and cooling system with parabolic trough collector field from the German company Soliterm on the roof of the new production hall of MM Graphia in Izmir in operation since 2022.

Photo: Mayr-Melnhof Graphia Izmir (link to https://solarthermalworld.org/news/solar-steam-to-cool-production-halls-in-southern-turkey/)

3 MW solar space heating and cooling system with parabolic trough collector field from the German company Soliterm on the roof of the new production hall of MM Graphia in Izmir in operation since 2022

Websites of organizations mentioned on this news article: